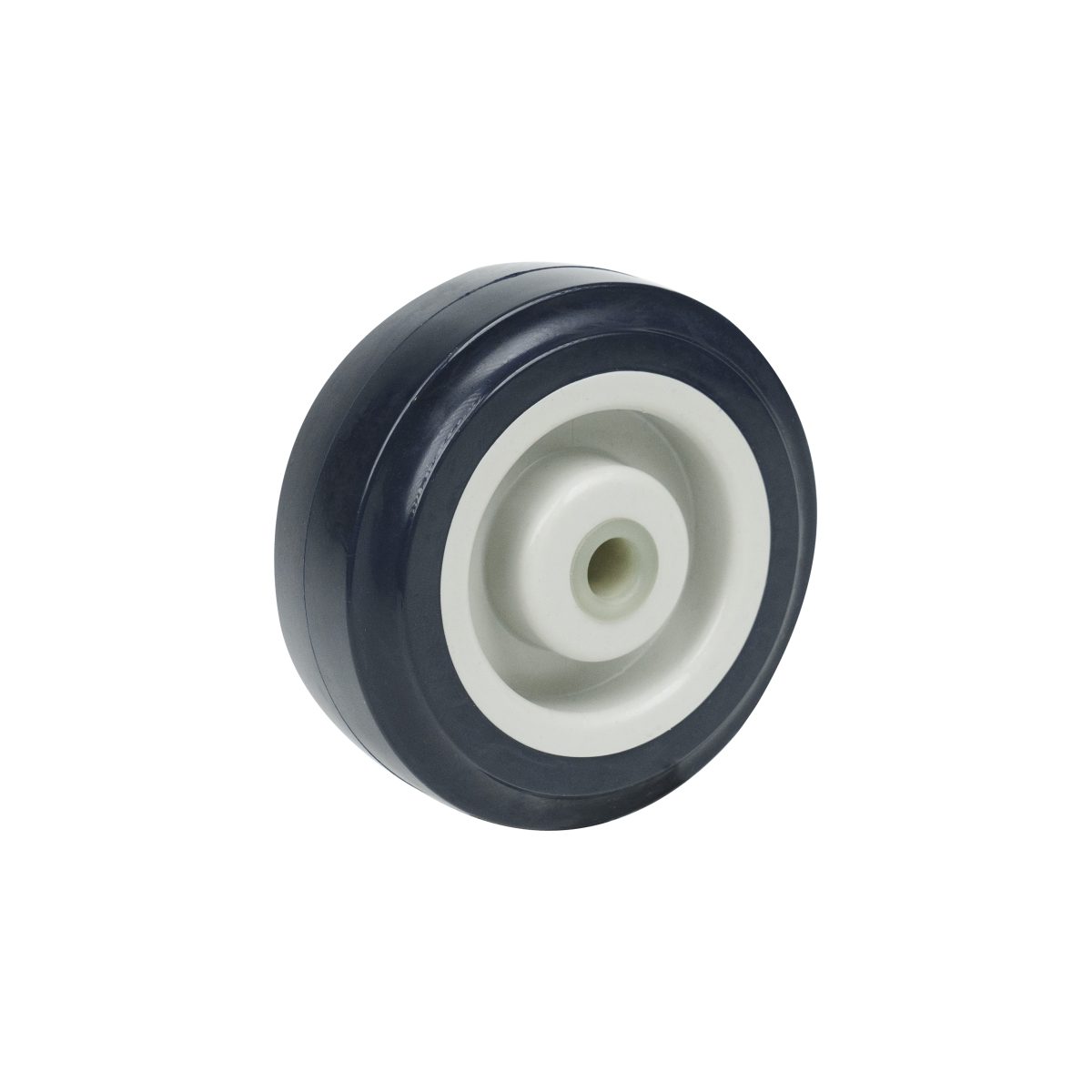

What is polyurethane caster?

When it comes to choosing the right caster wheels for various applications, the material of the casters plays a crucial role in determining their performance and suitability. One of the most popular and versatile materials used in caster manufacturing is polyurethane. Polyurethane casters are widely recognized for their durability, flexibility, and smooth operation. In this blog, we’ll explore what polyurethane casters are, their benefits, applications, and how to choose the right ones for your needs.

What is Polyurethane?

Polyurethane is a versatile polymer that can be manufactured in a range of forms, including foams, coatings, and elastomers. It is known for its flexibility, toughness, and resistance to various environmental factors. In caster wheels, polyurethane is typically used as a coating over a core material, such as steel or plastic, to enhance the wheel’s performance and durability.

Characteristics of Polyurethane Casters

Why use polyurethane wheels? Polyurethane wheels are favored for their versatility and performance across various applications. They offer a superior combination of hardness, durability, and grip compared to traditional materials like rubber or plastic. The ultimate advantage of polyurethane is its ability to absorb shocks and vibrations, which provides a smoother and quieter ride. This makes them ideal for use in skateboards, roller skates, and industrial casters. Additionally, polyurethane wheels have excellent resistance to abrasion and chemicals, ensuring a longer lifespan even in demanding environments. Their performance on different surfaces, coupled with their resilience, makes them a popular choice for both recreational and industrial purposes.

-

Durability

Polyurethane casters are known for their exceptional durability. The material is resistant to abrasion, impact, and wear, making these casters ideal for heavy-duty applications and environments with rough surfaces.

-

Load Capacity

Polyurethane casters can handle a significant amount of weight. The material’s strength and resilience enable the casters to support heavy loads without deforming or failing, which is essential in industrial and commercial settings.

-

Smooth Operation

One of the standout features of polyurethane casters is their ability to provide a smooth and quiet rolling experience. The material’s flexibility helps absorb shocks and vibrations, reducing noise and ensuring a more comfortable and efficient operation.

-

Floor Protection

Polyurethane casters are gentle on floors. Unlike harder materials like metal, polyurethane wheels are less likely to cause scratches, dents, or damage to delicate flooring surfaces, making them suitable for use in environments with sensitive floors.

-

Resistance to Chemicals

Polyurethane is resistant to a range of chemicals, including oils, acids, and solvents. This makes polyurethane casters ideal for use in environments where exposure to such substances is common, such as in laboratories or manufacturing facilities.

-

Temperature Tolerance

Polyurethane can withstand a range of temperatures, though extreme heat or cold can affect its performance. It generally performs well in moderate temperature conditions, maintaining its flexibility and strength.

Applications of Polyurethane Casters

Polyurethane casters are used in a wide variety of applications across different industries due to their versatility and performance characteristics. Some common applications include:

-

Industrial Settings

In factories and warehouses, polyurethane casters are used on equipment, carts, and trolleys that transport materials and goods. Their durability and load-bearing capacity make them ideal for handling heavy industrial loads.

-

Healthcare

In hospitals and medical facilities, polyurethane casters are used on hospital beds, wheelchairs, and medical carts. Their smooth and quiet operation is essential for providing a comfortable experience for patients and medical staff.

-

Retail and Hospitality

In retail stores and hotels, polyurethane casters are used on shopping carts, service carts, and furniture. Their floor protection qualities help maintain the appearance of floors in high-traffic areas.

-

Aerospace and Automotive

Polyurethane casters are employed in the aerospace and automotive industries for handling equipment and components. Their resistance to chemicals and wear ensures reliable performance in demanding environments.

Choosing the Right Polyurethane Casters

Selecting the right polyurethane casters involves considering several factors to ensure they meet the specific needs of your application:

-

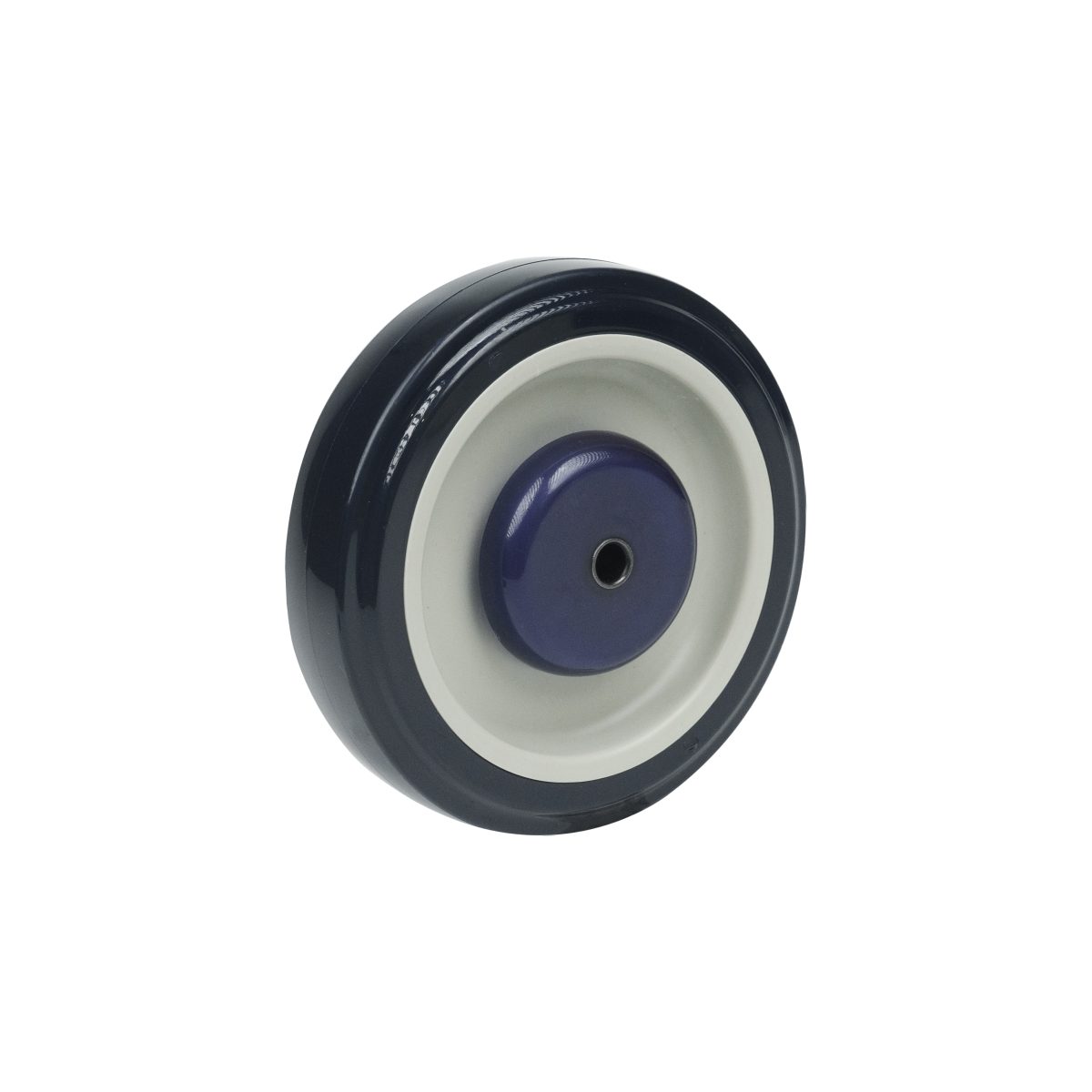

Load Capacity

Determine the maximum load that the casters need to support. Choose casters with a load capacity that exceeds the weight of the equipment or material being transported to ensure safety and longevity.

-

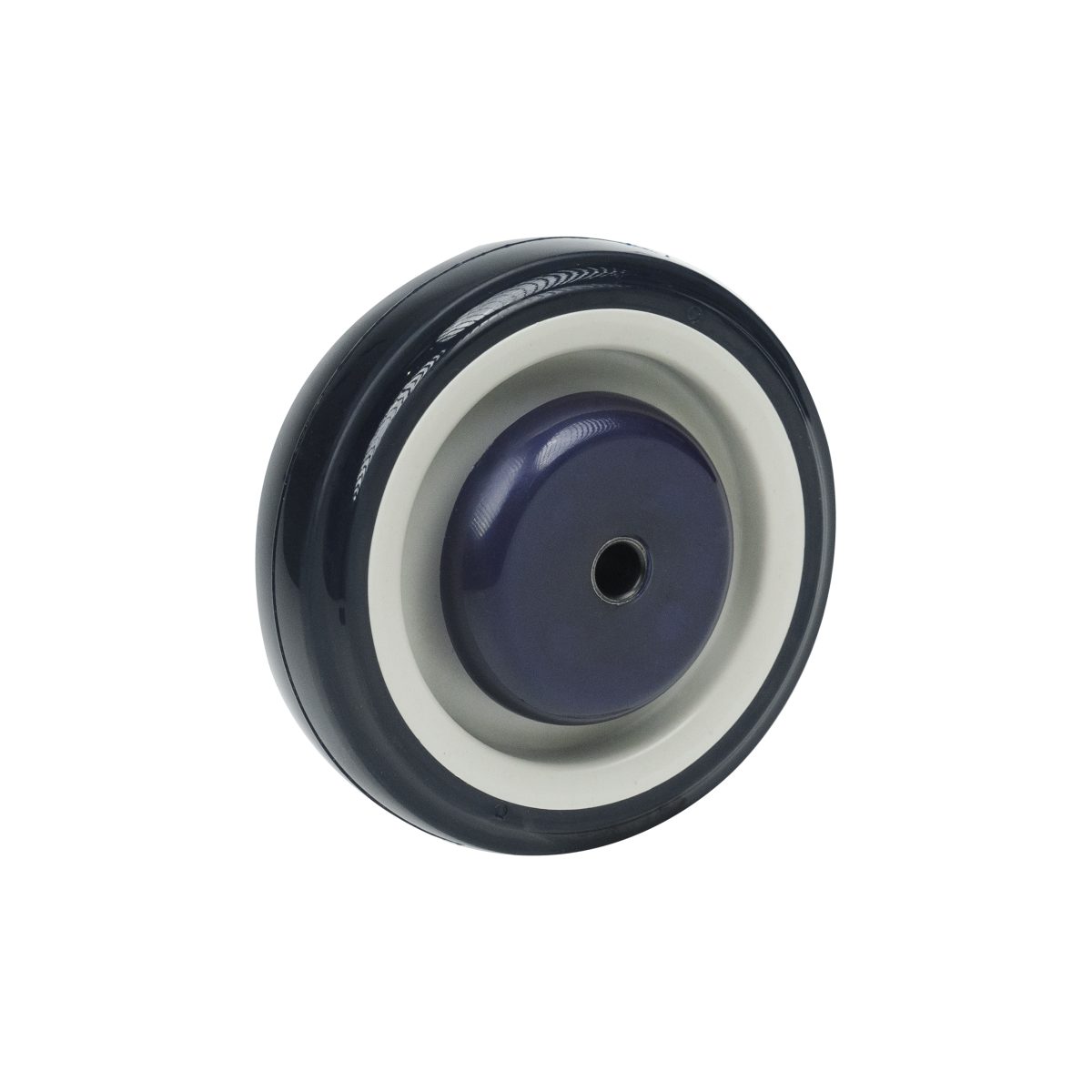

Wheel Size

The size of the caster wheels affects maneuverability and load distribution. Larger wheels generally provide better stability and smoother rolling, especially on uneven surfaces. TARGET Casters are available in a wide selection of sizes.

-

Hardness

Polyurethane casters come in different hardness levels, typically measured in Shore A durometer. Softer wheels offer better shock absorption and grip, while harder wheels provide increased durability and load-bearing capacity.

-

Mounting Type

Casters are available with various mounting options, including plate mounts, stem mounts, and swivel designs. Choose the mounting type that is compatible with your equipment and ensures ease of installation.

-

Environmental Factors

Consider the environmental conditions where the casters will be used. For example, if exposure to chemicals or extreme temperatures is a concern, ensure the casters are designed to withstand those conditions.

Conclusion

Polyurethane casters are an excellent choice for many applications due to their durability, smooth operation, and ability to protect floors. Their versatility makes them suitable for use in industrial, healthcare, retail, and numerous other settings. By understanding the characteristics and benefits of polyurethane casters and carefully considering your specific needs, you can select the most appropriate casters to enhance the performance and efficiency of your equipment and operations.