What Is an Anti-Static Wheel?

When shopping in a mall, you may notice a slight electric shock when touching the shopping cart. This phenomenon occurs due to static electricity generated by the friction between the wheels and the floor. Anti-static wheels are specifically designed to eliminate static buildup, providing a safer and more comfortable experience. These wheels are widely used in various industries to protect sensitive equipment and ensure operational safety.

What Is an Anti-Static Wheel?

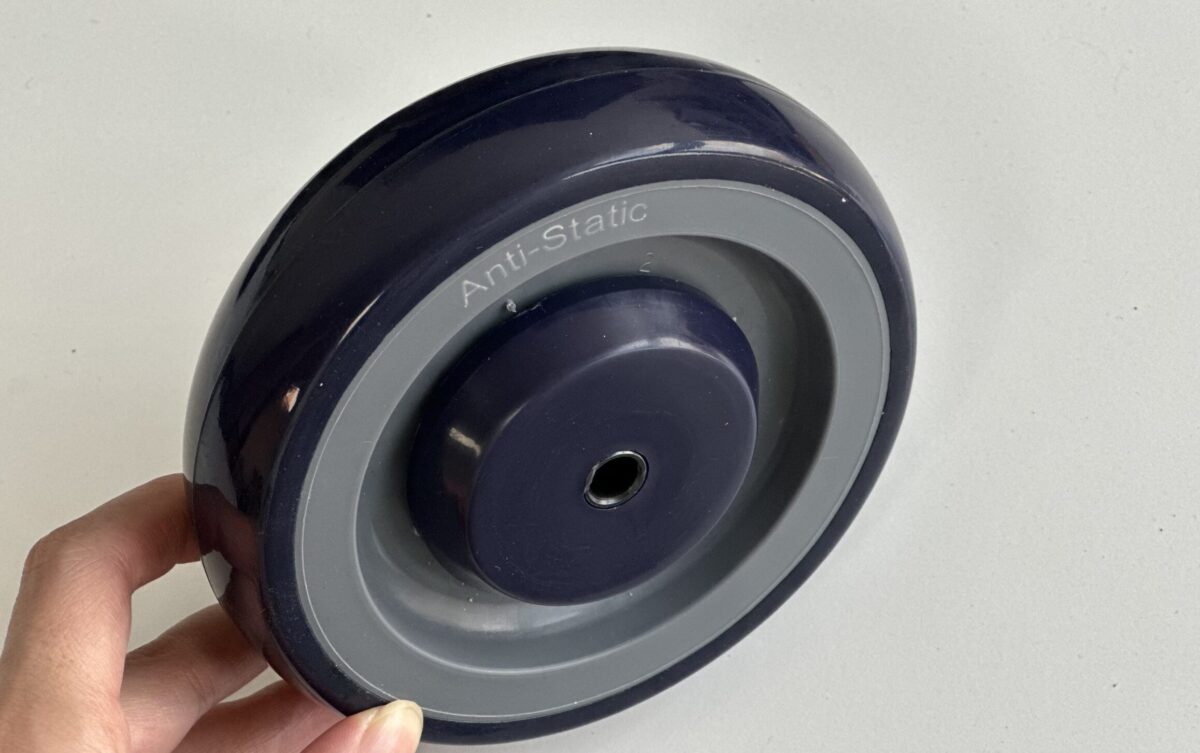

An anti-static wheel is a specialized caster designed to prevent the buildup of static electricity by dissipating electrical charges safely to the ground. Made from conductive or dissipative materials, these wheels are commonly used in environments where static electricity can damage sensitive equipment or create safety hazards.

How Do Anti-Static Wheels Work?

Anti-static wheels work by allowing electrical charges to flow through the wheel material and safely discharge to the ground. Traditional caster wheels generate friction between the floor and the wheel, which can cause static electricity to build up over time. In contrast, anti-static caster wheels are manufactured with materials that have low electrical resistance, ensuring that any accumulated charge is immediately dissipated.

Why Are Anti-Static Wheels Important?

Static electricity may seem harmless, but in environments such as electronics manufacturing, healthcare facilities, and industrial plants, it can pose significant risks. Static discharge can damage sensitive electronic components, ignite flammable materials, or interfere with precise instrumentation. Anti-static casters wheels mitigate these risks by preventing the buildup and sudden discharge of static electricity.

What Is a Good Anti-Static Material?

Choosing the right material for anti-static wheels is essential to ensure effective static dissipation. The most commonly used anti-static materials include:

- Thermoplastic Rubber (TPR): TPR anti-static wheels combine elasticity and durability, making them ideal for industrial and commercial applications. TPR wheels offer excellent shock absorption, reducing vibration while maintaining anti-static properties.

- Polyurethane (PU): PU wheels provide high load capacity and excellent wear resistance while maintaining anti-static properties. These wheels are widely used in environments where durability and smooth movement are essential.

- Rubber: Anti-static rubber wheels are highly effective in dissipating static charges while providing superior traction and quiet operation. Rubber’s natural conductivity can be enhanced with anti-static additives to ensure consistent ESD protection. These wheels are commonly used in environments where a combination of shock absorption, noise reduction, and anti-static performance is required.

- Conductive Polypropylene (PP): PP material offers high impact resistance and is often used for anti-static casters in cleanroom environments. It provides lightweight yet durable performance, making it suitable for delicate operations.

- Carbon-Loaded Nylon: This material is infused with carbon fibers to enhance conductivity and ensure consistent static dissipation. It is a popular choice for applications requiring high-strength wheels with anti-static properties.

What Is the Purpose of Anti-Static?

The primary purpose of anti-static wheels is to prevent electrostatic discharge (ESD) by ensuring that static electricity does not accumulate on the surface of the wheel or the equipment it supports. Key objectives include:

- Protecting Sensitive Equipment: Anti-static wheels prevent the buildup of charges that can damage electronic circuits or disrupt delicate instruments.

- Ensuring Workplace Safety: By dissipating static electricity, these wheels reduce the risk of sparking, which can ignite flammable substances in hazardous environments.

- Improving Product Longevity: Reducing static-related wear and tear on equipment helps extend the operational lifespan of machinery and tools.

- Maintaining Cleanroom Standards: In environments where cleanliness and static control are critical, such as semiconductor manufacturing, anti-static casters help maintain required standards.

What Are the Applications of Anti-Static Wheel?

Anti-static wheels find applications in diverse industries where static control is essential. Common uses include:

1. Electronics Manufacturing and Assembly

Anti-static casters are used in workstations, carts, and shelves that handle sensitive electronic components.

Prevents electrostatic discharge that can damage circuit boards and microchips.

2. Cleanroom Environments

Used in semiconductor fabrication, pharmaceutical production, and biotech research labs.

Maintains a static-free and contaminant-free environment, ensuring process stability.

3. Hospital and Healthcare Facilities

Anti-static wheels on medical carts, beds, and equipment protect sensitive diagnostic and therapeutic devices.

Ensures the safety of both patients and healthcare professionals.

4. Industrial and Hazardous Environments

Ideal for environments where explosive or flammable substances are present.

Reduces the risk of ignition caused by static discharge.

5. Retail and Commercial Spaces

Shopping carts and stock trolleys equipped with anti-static wheels prevent static shocks to customers and staff.

Enhances customer experience and protects electronic payment terminals.

How to Choose the Right Anti-Static Wheels

When selecting anti-static wheels for your application, consider the following factors:

- Material Compatibility: Ensure the wheel material is compatible with the operating environment.

- Load Capacity: Choose wheels that can handle the expected weight without compromising performance.

- Surface Type: Consider the type of flooring to ensure smooth and safe movement.

- Electrical Resistance Requirements: Select wheels with the appropriate level of conductivity or dissipative properties.

Find the Best Anti-Static Casters Wheels Today

Anti-static wheels are essential for protecting sensitive equipment and ensuring safety in various environments. By understanding their benefits and applications, you can choose the right wheels for your specific needs. Whether you’re working in electronics manufacturing or hazardous environments, anti-static casters wheels provide the reliability and protection you need.

Upgrade your equipment with high-quality anti-static wheels to ensure safety and operational efficiency.