Polyurethane vs Rubber Casters: Which Suits You Better?

When it comes to selecting casters for your equipment, furniture, or industrial applications, the choice between polyurethane and rubber casters can significantly impact performance, durability, and overall effectiveness. Understanding the differences between these two materials is essential to making an informed decision that best meets your needs. In this article, we’ll delve into the key characteristics, advantages, and disadvantages of polyurethane and rubber casters, helping you to make the right choice for your specific applications.

Understanding Casters

Casters are an integral part of many moving systems. They allow for smooth mobility in various settings, from industrial environments to home furniture.

The two most common materials used in caster wheels are polyurethane and rubber, each offering unique properties that can enhance or hinder functionality depending on the application.

What Are Polyurethane Casters?

Polyurethane casters are made from a type of synthetic polymer known for its versatility and resilience. These casters are known for their strength and durability, making them a popular choice for heavy-duty applications. Polyurethane casters are often designed with a rigid core, typically made of metal or plastic, which adds to their stability and weight-bearing capacity.

Key Characteristics of Polyurethane Casters:

-

Hardness:

Typically harder than rubber, polyurethane can bear heavier loads and resist deformation over time.

-

Durability:

Polyurethane casters are resistant to abrasion, chemicals, and oil, which makes them suitable for harsh environments.

-

Noise Reduction:

They provide a quieter operation compared to metal or plastic wheels, making them ideal for use in noise-sensitive areas.

-

Smooth Rolling:

Polyurethane casters offer low rolling resistance, allowing for easier movement on various surfaces.

Polyurethane Wheels Provided by TARGET Casters |

|||||||

Part name |

TARGET Number |

Material |

Wheel Diameter |

Wheel Tread Width |

Assembly Hole Diameter |

Bearing |

Load Capacity |

| 2″Polyurethane Wheel | 33W PU05001 | Polyurethane | 2″ | 0.79″ | 9mm | Dual Precision Ball Bearings | 176lbs |

| 3″Polyurethane Wheel | 33W PU07501 | Polyurethane | 3″ | 0.87″ | 8mm | Plastics Bushing | 250lbs |

| 4″Light Duty Polyurethane Wheel | 33W PU10001 | Polyurethane | 4″ | 1-1/4″ | 8mm | Dual Precision Ball Bearings | 290lbs |

| 5″Light Duty Polyurethane Wheel | 33W PU12501 | Polyurethane | 5″ | 1-1/4″ | 8mm | Dual Precision Ball Bearings | 290lbs |

| 6″ Medium Duty Polyurethane Wheel | 33W PU15001 | Polyurethane | 6″ | 2″ | 12.8mm | Dual Precision Ball Bearings | 880lbs |

| 8″ Heavy Duty Polyurethane Wheel | 33W PU20001 | Polyurethane | 8″ | 2″ | 12.8mm | Dual Precision Ball Bearings | 990lbs |

| 8″ Heavy Duty Needle Roller Bearings Polyurethane Wheel | 33W PU20002 | Polyurethane | 8″ | 2″ | 13.3mm | Precision Needle Roller Bearing | 990lbs |

What Are Rubber Casters?

Rubber casters, on the other hand, are made from natural or synthetic rubber. They are known for their flexibility and shock-absorbing properties, making them an excellent choice for applications requiring gentle handling or noise dampening.

Key Characteristics of Rubber Casters:

-

Flexibility:

Rubber casters can easily adapt to uneven surfaces, providing better traction and grip.

-

Shock Absorption:

The natural cushioning properties of rubber help absorb impacts, making them ideal for transporting fragile items.

-

Chemical Resistance:

While rubber does have some resistance to chemicals, it can degrade more quickly than polyurethane in harsh environments.

-

Affordability:

Rubber casters are often more cost-effective than their polyurethane counterparts.

Part of the RUBBER Casters provided by TARGET Casters |

||||||||

Part name |

TARGET Number |

Material |

Wheel Diameter |

Wheel Tread Width |

Overall Height |

Installation information |

Bearing |

Load Capacity |

| 3″ Light Duty 304 Stainless Steel Rubber Threaded Stem Swivel Caster | TC-RBTSA075-01 | Rubber + Stainless Steel | 3″ φ75mm |

1.25″ 32mm |

4.3″ 110mm |

Threaded Stem:3/8″-16 Stem length:1-1/8″ |

Bushing/ Dual stainless steel Precision Ball Bearings |

114kg(250lbs) |

| 5″ Rubber Warehouse Logistics Wheel | 33W RB12501 | Thread material : Rubber, 70-75° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.46″ 37mm |

5″ φ125mm |

Assembly Hole Diameter: 15mm(0.6″) |

6202 Roller bearing | 150 kg (330 lbs) |

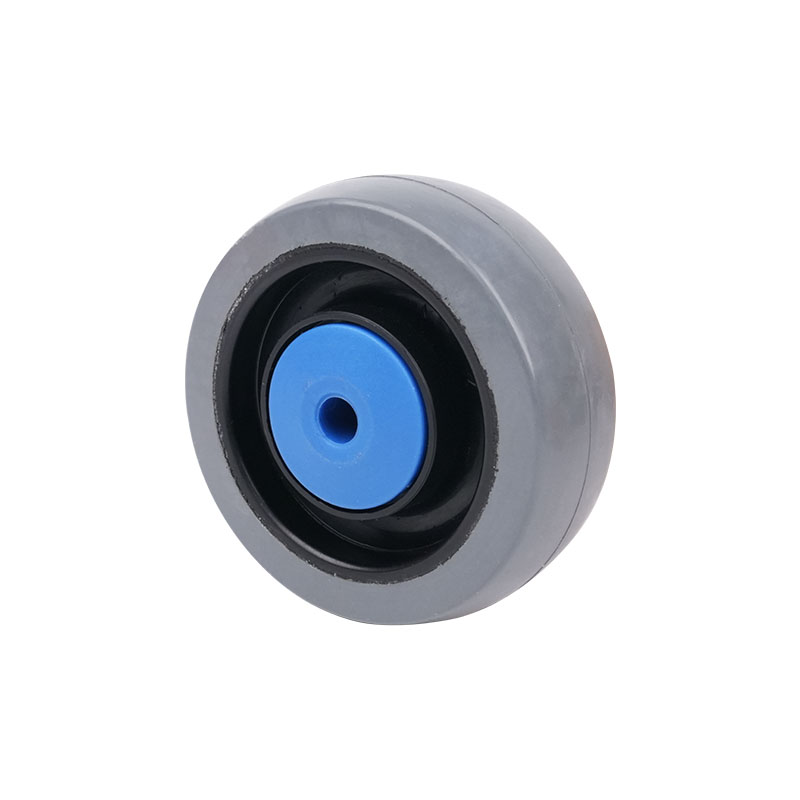

| 5″ Rubber Grey Silent Wheel | 33W RB12502 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

| 4″ Rubber Grey Wheel | 33W RB10001 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

4″ φ100mm |

1.42″ 36mm |

4″ φ100mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 70 kg(154 lbs) |

| 5″ Rubber Black Silent Wheel | 33W RB12503 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

Comparing Performance

When deciding between polyurethane and rubber casters, consider the following factors:

-

Load Capacity

Polyurethane casters generally offer a higher load capacity than rubber casters. If you need to move heavy equipment or products, polyurethane may be the better option. For lighter loads, rubber casters can suffice.

-

Surface Compatibility

Both types of casters perform well on smooth surfaces. However, rubber casters excel on uneven or rough surfaces, as their flexibility allows them to conform better. If your application involves navigating over bumps or debris, rubber may be the preferable choice.

-

Environmental Considerations

If your application involves exposure to harsh chemicals, oils, or extreme temperatures, polyurethane casters will typically last longer due to their superior chemical resistance. In contrast, rubber casters may wear out more quickly under these conditions.

-

Noise Levels

Polyurethane casters are generally quieter than rubber casters, making them ideal for environments where noise is a concern, such as offices or healthcare facilities. Rubber casters, while also quieter than metal, may produce more noise during operation.

-

Maintenance and Lifespan

Polyurethane casters tend to have a longer lifespan due to their durability and resistance to wear. While rubber casters may be less expensive upfront, they might require more frequent replacement, especially in demanding applications. Regular maintenance, such as checking for wear and tear, can prolong the life of both types of casters.

-

Cost Considerations

Cost is often a determining factor in the decision-making process. Rubber casters are typically less expensive than polyurethane options. However, it’s essential to consider the long-term value. Investing in polyurethane casters may save you money over time due to their durability and reduced need for replacement.

Applications and Use Cases

Polyurethane Casters

-

Industrial Applications:

For manufacturing and warehousing where heavy loads are common.

-

Transportation of Equipment:

Ideal for trolleys or carts that carry substantial weight.

-

Use on Smooth Surfaces:

Perfect for environments like hospitals, offices, and warehouses where noise reduction is beneficial.

Rubber Casters

-

Fragile Loads:

Best for transporting delicate items, such as glass or electronics.

-

Rough Terrain:

Suitable for outdoor applications or uneven surfaces.

-

Cost-sensitive Situations:

Good for projects with budget constraints where performance is still necessary.

Conclusion

Choosing between polyurethane and rubber casters depends on your specific needs, including load capacity, surface compatibility, environmental factors, and budget. While polyurethane casters excel in durability and performance under heavy loads, rubber casters offer flexibility and cost-effectiveness in less demanding applications. By understanding the characteristics of each type, you can make an informed decision that enhances the efficiency and effectiveness of your equipment.

Before placing an order, consider your application requirements carefully. We encourage you to reach out to our knowledgeable team if you have any questions or need further assistance in selecting the perfect casters for your needs. Contact us today at +86 18958308581 to discuss your caster product options, including the differences between polyurethane and rubber casters. We’re here to help with all your needs!