What Are the Rubber Caster Wheels?

What is a rubber caster wheel?

A rubber caster wheel is a mobility component made of rubber, offering smooth rolling, shock absorption, and floor protection in various applications.

Rubber caster wheels are widely used, but are they the right choice for your needs? Let’s explore their advantages, types, and drawbacks.

Are Rubber Casters Better?

Rubber caster wheels are preferred in many situations because they provide excellent traction, absorb shocks, and roll quietly. Compared to hard plastic or metal wheels, rubber casters reduce noise and vibration, making them ideal for indoor environments. However, they may wear faster under heavy loads or rough surfaces.

What Are the Solid Rubber Caster Wheels?

Solid rubber caster wheels are a type of rubber wheel made entirely from rubber material rather than being coated over a core. They offer durability, comfort, and good grip on various surfaces. These wheels do not require air, eliminating the risk of punctures, making them suitable for industrial and commercial applications.

Part of the RUBBER casters provided by TARGET Casters |

||||||||

Part name |

TARGET Number |

Material |

Wheel Diameter |

Wheel Tread Width |

Overall Height |

Installation information |

Bearing |

Load Capacity |

| 3″ Light Duty 304 Stainless Steel Rubber Threaded Stem Swivel Caster | TC-RBTSA075-01 | Rubber + Stainless Steel | 3″ φ75mm |

1.25″ 32mm |

4.3″ 110mm |

Threaded Stem:3/8″-16 Stem length:1-1/8″ |

Bushing/ Dual stainless steel Precision Ball Bearings |

114kg(250lbs) |

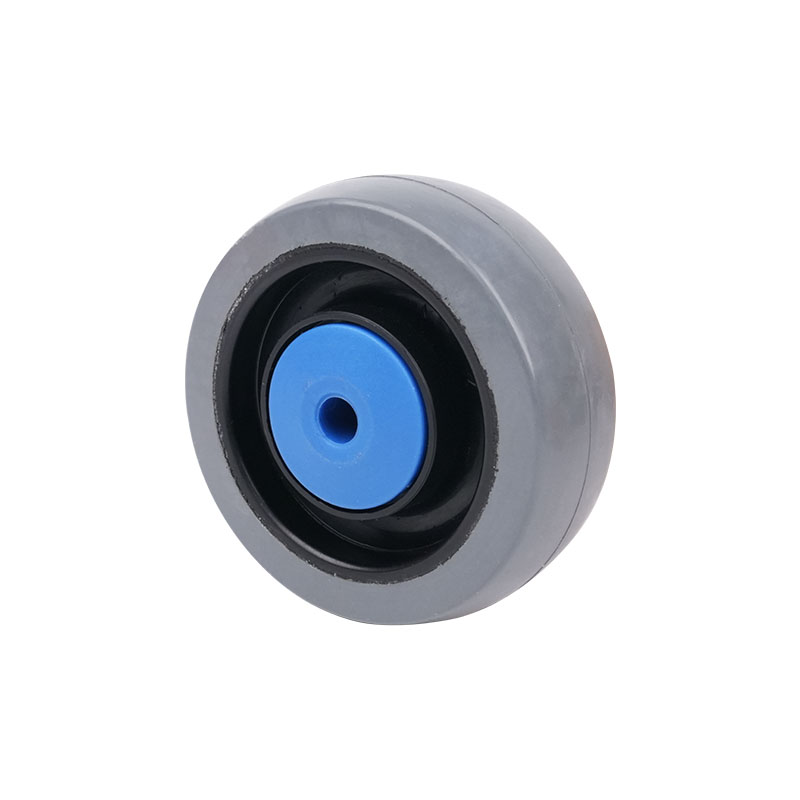

| 5″ Rubber Warehouse Logistics Wheel | 33W RB12501 | Thread material : Rubber, 70-75° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.46″ 37mm |

5″ φ125mm |

Assembly Hole Diameter: 15mm(0.6″) |

6202 Roller bearing | 150 kg (330 lbs) |

| 5″ Rubber Grey Silent Wheel | 33W RB12502 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

| 4″ Rubber Grey Wheel | 33W RB10001 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

4″ φ100mm |

1.42″ 36mm |

4″ φ100mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 70 kg(154 lbs) |

| 5″ Rubber Black Silent Wheel | 33W RB12503 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

What Are the Benefits of Elastic Rubber Caster Wheels?

Elastic rubber caster wheels have enhanced flexibility and resilience, allowing smoother movement and better shock absorption. Their key benefits include:

1. Superior Shock Absorption

Elastic rubber caster wheels effectively absorb shocks and vibrations, making them ideal for transporting fragile goods. They cushion the impact of uneven surfaces, reducing stress on transported items and ensuring smooth movement. This feature is particularly useful in warehouses, hospitals, and laboratories where stability is crucial.

2. Excellent Floor Protection

Compared to hard plastic or metal wheels, rubber caster wheels are gentler on flooring. They prevent scratches, scuffs, and dents, making them suitable for hardwood, tile, and epoxy-coated floors. Businesses and homeowners benefit from the protection these wheels offer, especially in environments with delicate surfaces.

3. Quiet and Smooth Operation

One of the biggest advantages of rubber caster wheels is their noise reduction capability. Elastic rubber caster wheels roll smoothly and quietly, making them ideal for hospitals, offices, libraries, and residential areas where noise minimization is essential. Unlike metal or hard plastic wheels, they do not create loud rolling sounds on hard surfaces.

4. Increased Traction and Grip

Elastic rubber caster wheels provide excellent traction, reducing the risk of slippage on smooth or wet surfaces. Their high-friction material ensures better control, making them a reliable choice for industrial carts, medical equipment, and warehouse trolleys. Enhanced grip improves safety and prevents accidents, especially in high-traffic areas.

5. Durability and Long Lifespan

High-quality rubber caster wheels are designed to withstand frequent use and various environmental conditions. Their elastic composition resists wear and tear, making them a long-lasting option for heavy-duty applications. They are less prone to cracking or breaking compared to lower-quality rubber wheels.

6. Versatile Applications

Elastic rubber caster wheels are widely used in multiple industries, including:

-

Medical Equipment

Hospitals use them for quiet and smooth patient transport.

-

Industrial Carts and Dollies

Provide ease of movement in warehouses and factories.

-

Office and Home Furniture

Protect floors while ensuring smooth mobility.

-

Retail and Hospitality

Shopping carts and service trolleys benefit from their quiet operation.

7. Resistant to Harsh Environments

Unlike some standard rubber caster wheels, elastic rubber models can resist chemicals, oils, and extreme temperatures. This makes them ideal for use in manufacturing plants, laboratories, and food processing facilities where exposure to harsh substances is common.

8. Reduced Rolling Resistance

Elastic rubber caster wheels require less effort to move loads compared to standard rubber wheels. Their design allows for smoother rolling, improving maneuverability and reducing strain on workers pushing carts or equipment.

What Are the Disadvantages of Rubber Caster Wheels?

1. Faster Wear and Tear

Compared to other materials, rubber caster wheels wear out faster, especially under heavy loads or rough surfaces. Over time, frequent use can cause cracks, reducing their lifespan.

2. Higher Rolling Resistance

Rubber caster wheels have more friction than metal or polyurethane wheels, requiring more effort to push or pull heavy loads. This can increase energy consumption in industrial settings.

3. Potential Floor Marking

Some rubber caster wheels leave black streaks or marks on smooth surfaces, such as hardwood or tile floors. Non-marking rubber wheels can help reduce this issue but may not completely eliminate it.

4. Limited Load Capacity

While rubber caster wheels offer shock absorption, they are not the best choice for carrying extremely heavy loads. Excessive weight can cause deformation, reducing performance.

5. Susceptible to Environmental Conditions

Extreme heat, oil, chemicals, and prolonged exposure to sunlight can cause rubber caster wheels to harden, crack, or degrade over time. This makes them less durable in harsh environments.

Conclusion

Rubber caster wheels offer comfort, quietness, and shock absorption, but they wear faster under heavy loads.

Choosing the right caster wheel for your application can be overwhelming, but we’re here to help! We offer a wide range of high-quality rubber caster wheels to meet all your needs. Contact us today to find the perfect solution for your equipment!

ORDER ONLINE OR GET IN TOUCH WITH OUR TECHNICAL SUPPORT TEAM ON sales02@targetcasters.com.