How To Make Caster Wheels Quieter?

Caster wheels, essential components in many daily-use items like office chairs, carts, and furniture, can often produce unwanted noise. Whether it’s the squeaky sound of a rolling office chair or the rattling of a shopping cart, the noise can be distracting and annoying. Fortunately, there are several strategies to make caster wheels quieter, ranging from material selection to maintenance practices. In this article, we will explore the key factors that influence caster wheel noise and provide practical tips for reducing it.

1. Choose the Right Material for the Caster Wheel

The material of the caster wheel plays a significant role in the noise it generates. Harder materials tend to produce more noise when rolling on hard surfaces, while softer materials provide a quieter experience.

-

Rubber Wheels

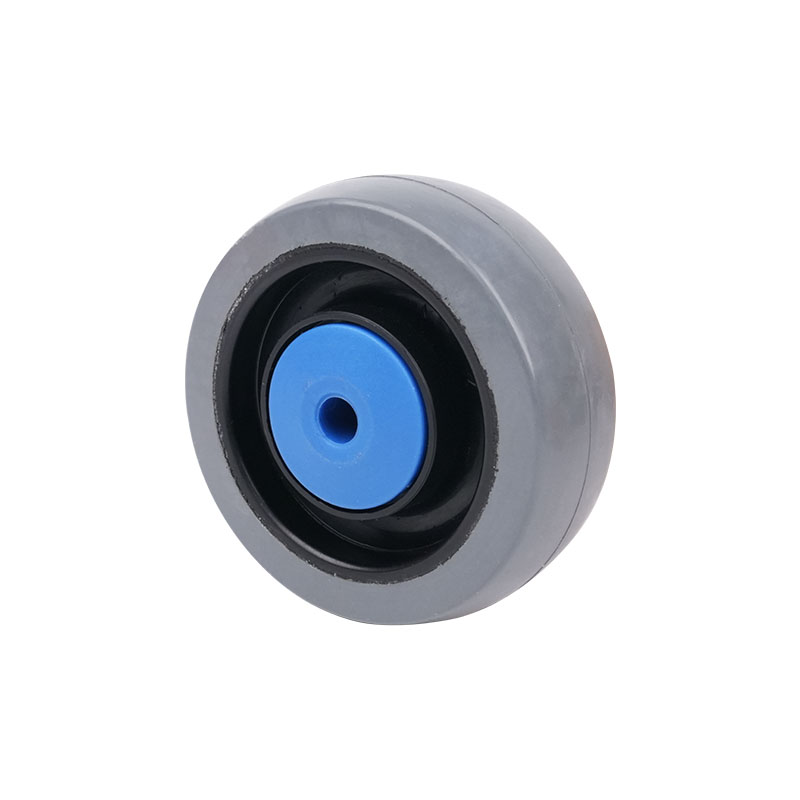

Soft rubber or polyurethane wheels are among the quietest options. They provide a cushioned roll that minimizes noise by absorbing vibrations. Rubber also has a natural damping effect, reducing the sound generated by friction.

-

Polyurethane (PU) Wheels

Polyurethane wheels are also known for their quiet operation. They combine the durability of plastic with the noise-damping properties of rubber. PU wheels are particularly effective on hard surfaces like tile or concrete.

-

Nylon or Plastic Wheels

While durable, these wheels are often louder than rubber or polyurethane, as they lack the shock-absorbing qualities of softer materials. If noise is a major concern, it is best to avoid using these types of wheels, especially on hard floors.

-

Soft TPR (Thermoplastic Rubber)

Another good choice for noise reduction is thermoplastic rubber, which offers a soft and smooth rolling experience, reducing noise significantly when compared to harder materials.

2. Select High-Quality Bearings

Bearings are the internal components that allow the caster wheel to rotate smoothly. Low-quality or worn-out bearings can cause the wheels to become noisy due to increased friction or irregular movement. Upgrading to high-quality bearings can make a significant difference in both the smoothness and quietness of your caster wheels.

-

Ball Bearings

Caster wheels that use ball bearings generally offer better smoothness and noise reduction. High-grade ball bearings, especially those with sealed or shielded designs, can prevent dust and debris from entering, ensuring a smoother and quieter operation.

-

Roller Bearings

While typically less common in caster wheels, roller bearings can be a good alternative for some applications. They are designed to reduce friction more effectively than ball bearings, which can translate into quieter performance.

-

Sealed Bearings

Sealed bearings prevent contaminants from entering the bearing system, reducing wear and tear. By keeping the bearings clean, you ensure a quieter and smoother roll.

3. Regular Maintenance and Lubrication

One of the easiest ways to reduce caster wheel noise is through regular maintenance. Over time, dirt, dust, and debris can accumulate in the wheels and bearings, causing them to grind and squeak. Additionally, bearings may dry out, leading to friction that increases noise.

-

Clean the Caster Wheels

Use a soft cloth to clean the wheels, especially around the axle and bearings. For stubborn dirt, a toothbrush or compressed air can help remove debris from hard-to-reach areas.

-

Lubricate the Bearings

Applying lubricant to the bearings helps to reduce friction and keeps the wheels rolling smoothly. Use a lubricant specifically designed for bearings, such as silicone-based or light machine oil. Avoid thick greases, as they can attract dust and dirt, leading to more noise.

-

Check for Worn Bearings

Over time, bearings can wear out, and if they become damaged or deformed, they can produce noise. If the wheel continues to make noise despite lubrication, consider replacing the bearings with a higher-quality set.

4. Ensure Proper Wheel Size and Weight Capacity

Another factor that can contribute to caster wheel noise is improper sizing or an incorrect weight capacity. If the wheels are too small for the load they carry, they can strain under the pressure, resulting in excessive noise.

-

Choose the Correct Wheel Size

Make sure that the caster wheels are appropriate for the size and weight of the object they are supporting. Larger wheels tend to roll more smoothly and are quieter, especially on rough surfaces.

-

Match the Weight Capacity

Ensure that the caster wheels are rated to handle the weight of the item they are attached to. Overloaded wheels are more likely to squeak and generate noise, as they will be under more strain.

5. Opt for Soft Flooring or Mats

The surface that the caster wheels roll on can also affect the amount of noise they produce. Hard surfaces like concrete, tile, or hardwood tend to amplify wheel noise, while softer surfaces can absorb it.

-

Use Floor Mats or Rugs

If possible, place a rug or mat under your furniture or equipment. The softer surface will cushion the movement of the caster wheels, reducing noise and protecting both the floor and the wheels.

-

Smooth Out Rough Surfaces

If you are using caster wheels on rough or uneven floors, consider smoothing the surface or using caster wheels designed to work on rough terrain. This can reduce the impact noise created by the wheels rolling over bumps or grooves.

6. Consider the Type of Caster

The design of the caster itself can influence how much noise it makes. Swivel casters, for example, have a rotating mechanism that can produce more noise compared to fixed casters, especially if they lack lubrication or are poorly constructed.

-

Fixed Casters

If noise reduction is a priority, consider switching to fixed casters for applications where movement in multiple directions is not required. Fixed casters tend to produce less noise because they have fewer moving parts.

-

Swivel Casters with Quality Bearings

If you need the maneuverability of swivel casters, make sure to select high-quality models with precision bearings. This will ensure smoother movement and quieter operation.

7. Check for Misalignment or Damage

Lastly, misalignment or damage to the caster wheels can also lead to noisy operation. When the wheel and axle are not properly aligned, it can cause uneven rolling, resulting in squeaks and rattles.

-

Inspect for Damage

Regularly inspect the caster wheels for signs of wear, cracks, or bent components. Replace any damaged parts promptly to ensure smooth and quiet movement.

-

Ensure Proper Installation

Check that the caster wheels are securely attached to the furniture or equipment. Loose or improperly installed casters can lead to rattling noises and reduced functionality.

Find the Best Noise-Reducing Casters Today

If you’re tired of the constant squeaks and rattles of your current caster wheels, it’s time to upgrade to a quieter solution. At TARGET Casters, we specialize in providing high-quality, noise-reducing casters designed to deliver smooth, quiet performance for a wide range of applications. Our casters are crafted from premium materials like soft rubber and polyurethane, ensuring optimal noise dampening, durability, and ease of movement.

Visit WEBSITE or contact us today to learn more about our products and how they can help transform your rolling experience!