8 Considerations for How to Choose the Right Heavy Duty Casters for Moving Heavy Equipment

Are you in the market for heavy duty casters to transport heavy equipment? Here are the top 8 factors to consider when selecting heavy duty casters and wheels for this purpose.

1. Select the Right Weight Rating for Heavy Duty Casters to Move Heavy Equipment

First, ensure the casters you choose are rated to handle the weight of your heavy equipment. This rating, known as weight capacity or load capacity, indicates the maximum load each heavy duty caster or wheel can support. This rating assumes intermittent use on smooth floors at speeds up to 3 mph, without shock loading or harsh environmental conditions.

Casters are categorized into three weight ranges: light duty (up to 500 lbs), medium duty (501 to 2,000 lbs), and heavy duty (over 2,000 lbs). Remember, each caster’s rating applies individually, whether it’s swivel or rigid, not to the entire set. Calculate the required weight capacity for each caster by adding the equipment’s weight to that of the cart, truck, or platform, then add 33% for safety. Divide this total by the number of casters to determine the appropriate rating for each one.

Choosing casters with insufficient ratings could lead to failure, risking damage to your equipment or injury to workers due to increased difficulty in moving the load.

2. Choose Heavy Duty Casters with Adequate Width and Diameter for Moving Heavy Equipment

For optimal ease of movement, larger heavy duty wheels on casters are preferable to smaller ones. They not only facilitate smoother motion but also possess greater strength to support heavier loads. Casters are available in diameters from 1 inch to 25 inches. For best results, select heavy duty casters with a diameter of at least 8 inches.

In addition to diameter, wider wheels are crucial for handling heavy loads. Casters come with wheel widths ranging from ½ inch to 8 inches. To ensure stability and support, choose casters with wheels that are a minimum of 3 inches wide.

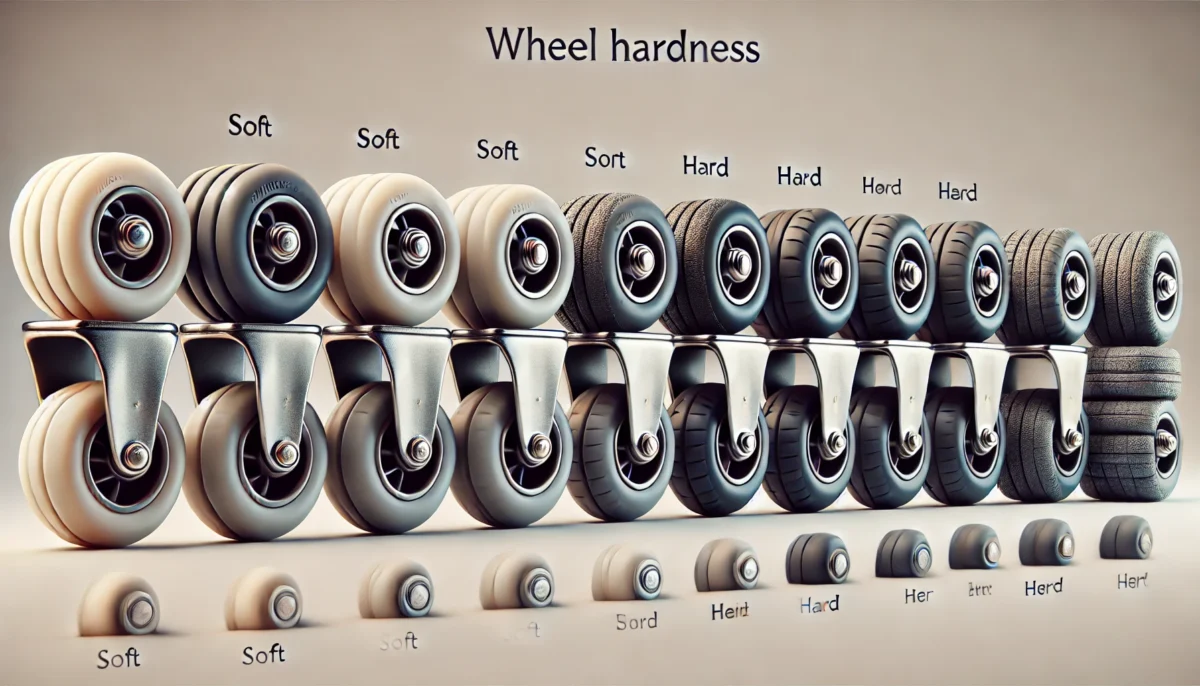

3. Choose the Right Wheel Hardness for Heavy Duty Casters

Casters for heavy equipment come in various materials such as cast iron, ductile steel, phenolic, nylon, and polyurethane. It’s crucial to select a wheel material that fits your specific needs.

Phenolic and other hard materials can trap staples, metal particles, and other debris, which can embed in the tread and eventually create grooves in floors, leading to expensive repairs.

In contrast, heavy duty casters made from durable polyurethane are less likely to collect debris. Their softer treads allow debris to bounce off, preventing floor damage and reducing maintenance costs.

4. Use Extended Swivel Leads for Heavy Duty Casters to Easily Move Heavy Equipment

Moving heavy loads is more challenging due to higher rolling resistance, which can cause lower-back injuries and physical strain—the leading cause of workplace injuries. The swivel lead, or swivel offset, is the distance between the vertical centerline of the heavy duty caster’s swivel section and the wheel’s vertical centerline. Casters with zero or standard swivel leads are more difficult to maneuver than those with extended swivel leads. For heavier loads, opting for heavy duty casters with extended swivel leads can greatly improve ease of movement.

5. Watch Out for Cheap Kingpins in Heavy Duty Casters for Heavy Equipment

Casters designed for moving heavy equipment can still fail prematurely, often due to issues with the kingpin. The kingpin, which can be a rivet, threaded stud, or bolt with a nut, connects the mounting plate and fork assembly of a swivel caster. Replacing a caster kingpin is costly and significantly impacts the overall cost of ownership. Therefore, when purchasing heavy duty casters for heavy equipment, avoid those with cheap kingpins. Opt for casters with high-quality components, such as forged kingpins.

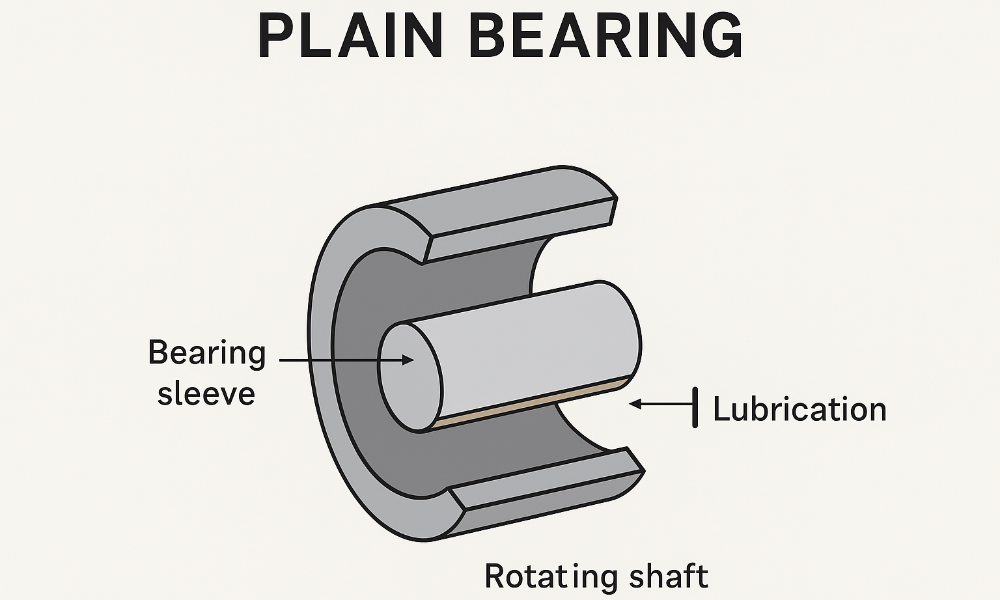

6. Opt for Low (or No) Maintenance Casters for Moving Heavy Equipment

Some heavy duty casters for heavy equipment require frequent greasing through a Zerk fitting to avoid seizing, or they feature open raceways that collect debris, damaging the caster and necessitating regular maintenance.

When purchasing heavy duty casters for heavy equipment, choose models that need no greasing and have designs that naturally keep debris out of the raceway. These low-maintenance casters tend to last longer and perform better, resulting in reduced downtime and increased productivity.

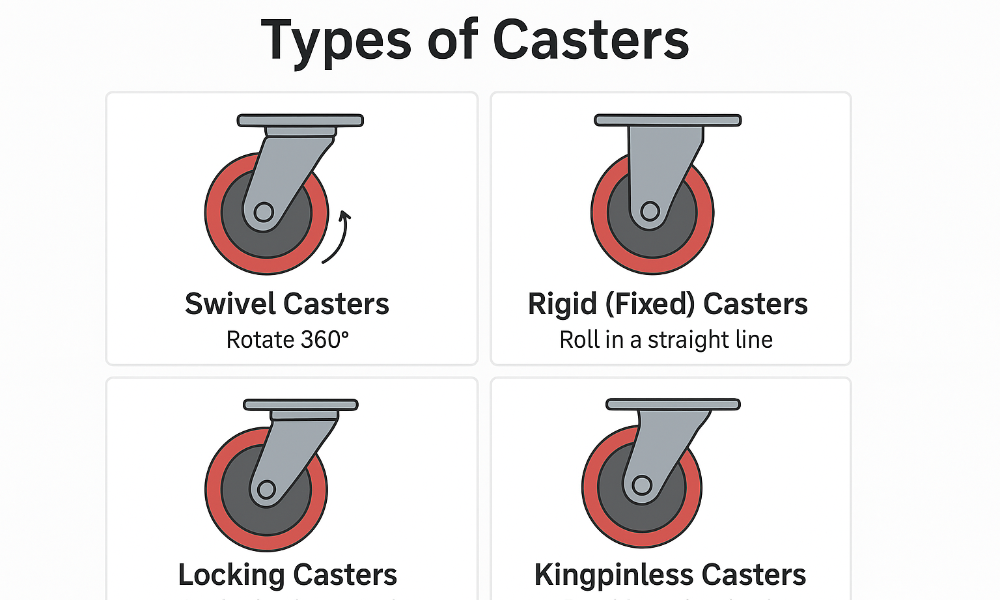

7. Choose the Right Number and Type of Casters for Moving Heavy Equipment

When selecting heavy duty casters for moving heavy equipment, it’s crucial to choose the correct number and type. Casters come in two main types: swivel and rigid. Swivel casters can rotate 360 degrees, while rigid casters are fixed and only move in one direction.

For typical industrial carts or platform trucks, four casters are usually used—two swivel at the front for maneuverability and two rigid at the back for directional control. However, for moving heavy equipment, increase the number of heavy duty casters to at least six. Place one swivel caster at each corner and one rigid caster at the midpoint of each of the two longest sides.

8. Use Brakes on Heavy Duty Casters for Moving Heavy Equipment

When dealing with heavy loads, the risk of accidents increases if the equipment starts to move unexpectedly. To mitigate this danger, invest in heavy duty casters equipped with brakes. These brakes will secure the wheels in place, preventing any unwanted movement when the equipment is not in use.

Conclusion

When selecting heavy equipment moving casters, it’s crucial to consider the manufacturer. Seek out a company that provides more than just basic wheels and swivels. Opt for a manufacturer with technical expertise and a proven track record of using a consultative approach to address challenges specific to moving heavy equipment.